Products>Piezoelectric products>Applied products

Piezoelectric element for ultrasonic motors Piezoelectric element for bimorph

Piezoelectric element for ultrasonic motors

| Operating principle | |

|---|---|

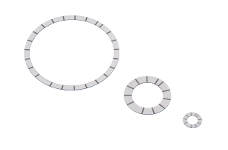

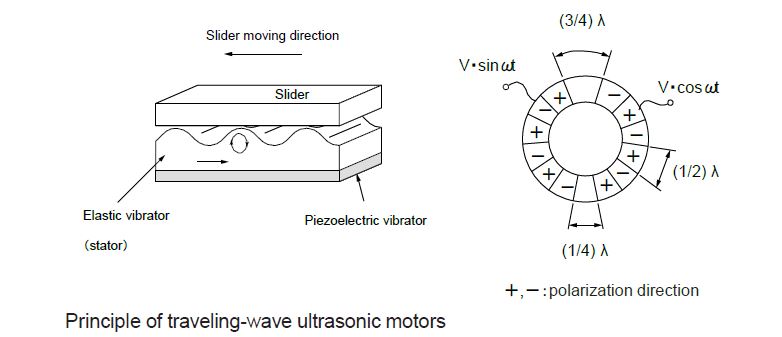

The operation principle of ultrasonic motor is shown in the figure below. High-order curling vibration is generated on the surface of the “elastic vibrator (stator)” and travelling waves are made by excitation of “piezoelectric vibrator”. And crimping the “slider” to stator with certain pressure will cause the “slider” to propagate on the stator by the friction between them. Driving force of ultrasonic motor is obtained by travelling-wave type elastic curling wave. This type of motor is named as a “traveling- wave ultrasonic motor”. To generate elastic curling wave on the elastic annular plate, adhere the “piezoelectric vibrator” beneath the elastic annular plate and exploit the expanding and contracting move. Elastic curling waves are generated on the elastic annular plate, by sectional expanding and contracting move when AC voltage is applied to the polarized “Piezoelectric vibrator” beneath the elastic annular plate. |

|

|

Piezoelectric element for bimorph

| Piezoelectric bimorph element | |||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||||||||

| Operational principle (Examples of parallel connection type) | |||||||||||||||||||||||||

|

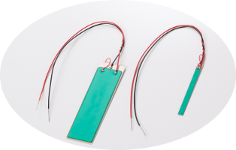

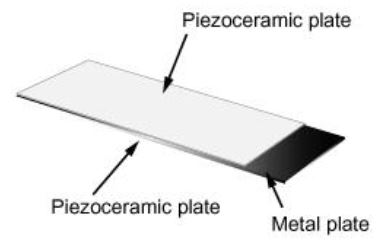

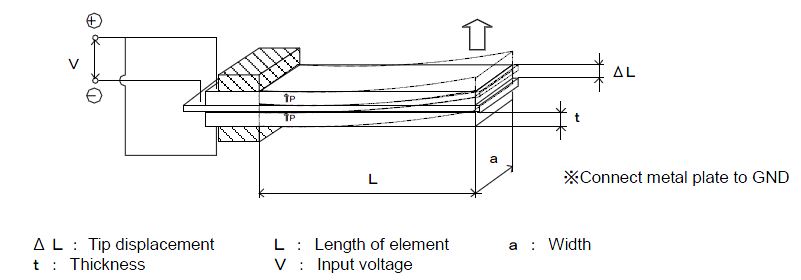

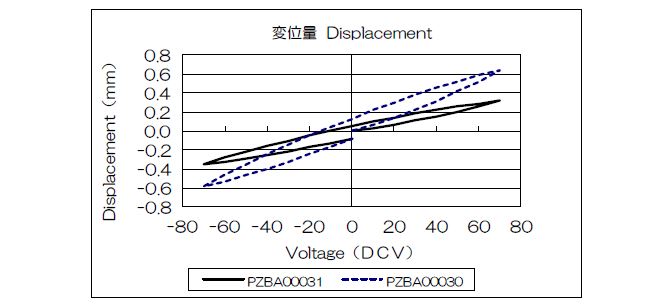

Piezoelectric bimorph element has a structure in which two “piezoelectric plates” polarized in the thickness direction are bonded to both sides of a “metal plate”. When “voltage (V)” is applied to this piezoelectric bimorph element, the upper “piezoelectric plate” contracts due to the piezoelectric lateral effect, and the lower “piezoelectric plate” expands. As a result, it will bend upward as a whole. (See the figure below) | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||

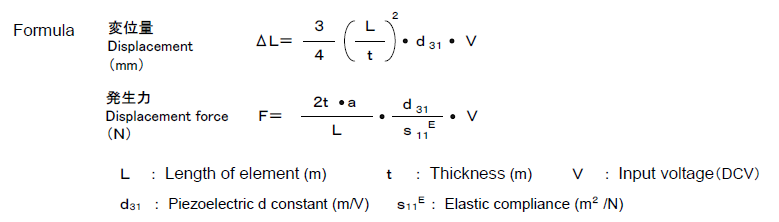

Electrical energy → mechanical energy The tip displacement (ΔL) and generated force (F) when voltage (V) is applied to the piezoelectric bimorph element are expressed by the following equations.

|

|||||||||||||||||||||||||

| Standard models | |||||||||||||||||||||||||

|

|||||||||||||||||||||||||